Viscometer

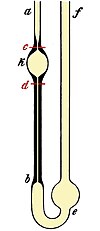

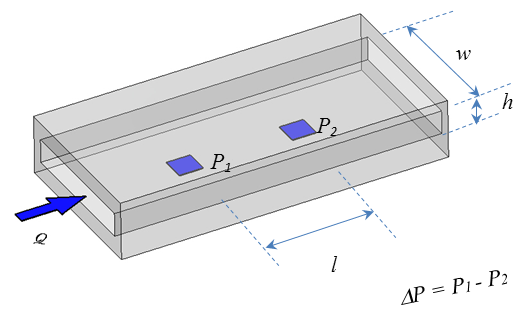

Another version is the Ubbelohde viscometer, which consists of a U-shaped glass tube held vertically in a controlled temperature bath.The time required for the test liquid to flow through a capillary of a known diameter of a certain factor between two marked points is measured.Stokes' law is the basis of the falling-sphere viscometer, in which the fluid is stationary in a vertical glass tube.If correctly selected, it reaches terminal velocity, which can be measured by the time it takes to pass two marks on the tube.A series of steel ball bearings of different diameter are normally used in the classic experiment to improve the accuracy of the calculation.This can be further improved by using a patented V plate, which increases the number of rotations to distance traveled, allowing smaller, more portable devices.The principle of viscosity measurement in this rugged and sensitive industrial device is based on a piston and cylinder assembly.The principle of operation can be adapted for many different conditions, making it ideal for process control environments.Electronics drive the piston into oscillatory motion within the measurement chamber with a controlled magnetic field.Improvements in sensitivity from modern electronics, is stimulating a growth in oscillating-piston viscometer popularity with academic laboratories exploring gas viscosity.Vibrational viscometers date back to the 1950s Bendix instrument, which is of a class that operates by measuring the damping of an oscillating electromechanical resonator immersed in a fluid whose viscosity is to be determined.Currently, many industries around the world consider these viscometers to be the most efficient system with which to measure the viscosities of a wide range of fluids; by contrast, rotational viscometers require more maintenance, are unable to measure clogging fluid, and require frequent calibration after intensive use.Vibrating viscometers are the most widely used inline instrument to monitor the viscosity of the process fluid in tanks, and pipes.The high-frequency electric field that is applied to the oscillator causes a movement of the sensor and results in the shearing of the fluid.Bode, who facilitated the detailed analysis of the electrical and mechanical transmission behavior of the oscillating system.[4] On the basis of this calibration, the quartz viscosimeter was developed which allows continuous viscosity determination in resting and flowing liquids.[8] An extension of this technique corrects the shift in the resonant frequency by the size of the drop deposited on the quartz crystal."Cup and bob" viscometers work by defining the exact volume of a sample to be sheared within a test cell; the torque required to achieve a certain rotational speed is measured and plotted.The tube is located in a temperature-controlled chamber ① and set such that the sphere is situated in the centre of the two magnets.The resulting Lorentz interaction between the magnetic field and these eddy currents generate torque that rotates the sphere.The outer cylinder of the Stabinger viscometer is a sample-filled tube that rotates at constant speed in a temperature-controlled copper housing.The hollow internal cylinder – shaped as a conical rotor – is centered within the sample by hydrodynamic lubrication[9] effects and centrifugal forces.An equilibrium rotor speed is established between driving and retarding forces, which is an unambiguous measure of the dynamic viscosity.The speed and torque measurement is implemented without direct contact by a Hall-effect sensor counting the frequency of the rotating magnetic field.The direct-time method uses a single 3-line times tube for determining the "bubble seconds", which may then be converted to stokes.[10] This method is considerably accurate, but the measurements can vary due to variances in buoyancy because of the changing in shape of the bubble in the tube.The Krebs Viscometer uses a digital graph and a small sidearm spindle to measure the viscosity of a fluid.[15] The flexible-blade rheometer improves the accuracy of measurements for the lower-viscosity liquids utilizing the subtle changes in the flow field due to the flexibility of the moving or stationary blade (sometimes called wing or single-side-clamped cantilever).

viscosityflow conditionsrheometerReynolds numberlaminar flowmPa·sWilhelm OstwaldUbbelohde viscometerNewtonian propertiesStokes' lawterminal velocitydensityglycerolpolymerGeorge Gabriel Stokesdrag forceReynolds numbersviscousNavier–Stokes equationsbuoyant forcegravitational forceStokes radiusgravitational accelerationStokes flowroughnessthixotropicviscosity controllerSaybolt universal secondcentipoiseprocess controlNewton's law of viscosityacidicenamelstainless steelquartz crystal microbalanceshear modulusTaylor vorticescentrifugal forcesfrictioneddy current braketorqueHall-effectmagnetic fieldoscillating U-tubeapparent viscosityextensional viscositynon-Newtonian fluidsrheometersMarsh funnelflow cupsrotating disk viscometerFlow measurementPoiseuille equationViscothermBibcodeAlcohol burnerBunsen burnerDesiccatorHeating mantleHot plateLab ovenMeker–Fisher burnerTeclu burnerWater bathVacuum dry boxChemostatHomogenizerLiquid whistleMagnetic stirrerMortar and pestleShakerSonicatorStatic mixerStirring rodVortex mixerWash bottleClampsClamp holderTripodBurette clampIron ringRetort standTest tube holderTest tube rackWire gauzeLab drying rackAgar plateCryogenic storage dewarIncubatorLaminar flow cabinetMicrotiter platePetri dishPicotiter plateRefrigeratorAspiratorAutoclaveCork borerCrucibleFilter paperForcepsCentrifugeMicroscopePipeclay triangleSpectrophotometerSplintStopperScoopulaSpatulaTest tube brushWire brushInoculation needleInoculation loopGlasswareDean–StarkSoxhlet extractorKipp'sBoston roundCondensersCold fingerLiebigEvaporatingSyracuseWatch glassFlasksBüchnerVacuum (Dewar)