Canning

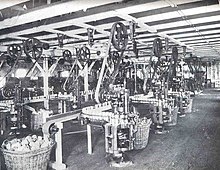

[3] Shortly before the Napoleonic Wars, the French government offered a hefty cash award of 12,000 francs to any inventor who could devise a cheap and effective method of preserving large amounts of food to create well-preserved military rations for the Grande Armée.Based on Appert's methods of food preservation, the tin can process was allegedly developed by Frenchman Philippe de Girard, who came to London and used British merchant Peter Durand as an agent to patent his own idea in 1810.[7] Bryan Donkin developed the process of packaging food in sealed airtight cans, made of tinned wrought iron.In 1824, Sir William Edward Parry took canned beef and pea soup with him on his voyage to the Arctic in HMS Fury, during his search for a northwestern passage to India.Studies in the 1980s attributed the lead from the cans as a factor in the disastrous outcome of the 1845 Franklin expedition to chart and navigate the Northwest Passage.Urban populations in Victorian Britain demanded ever-increasing quantities of cheap, varied, quality food that they could keep at home without having to go shopping daily.In response, companies such as Underwood, Nestlé, Heinz, and others provided quality canned food for sale to working class city-dwellers.The late 19th century saw the range of canned food available to urban populations greatly increase, as canners competed with each other using novel foodstuffs, highly decorated printed labels, and lower prices.After the war, companies that had supplied military canned food began to improve the quality of their goods for civilian sale.To prevent the food from being spoiled before and during containment, a number of methods are used: pasteurisation, boiling (and other applications of high temperature over a period of time), refrigeration, freezing, drying, vacuum treatment, antimicrobial agents that are natural to the recipe of the foods being preserved, a sufficient dose of ionizing radiation, submersion in a strong saline solution, acid, base, osmotically extreme (for example very sugary) or other microbially-challenging environments.The spores of the microorganism Clostridium botulinum (which causes botulism) can be eliminated only at temperatures above the boiling point of water.As a result, from a public safety point of view, foods with low acidity (a pH more than 4.6) need sterilization under high temperature (116–130 °C).To make a sanitary can and lid suitable for double seaming, manufacture begins with a sheet of coated tin plate.Precision is required to ensure that the welded sides are perfectly aligned, as any misalignment will cause inconsistent flange shape, compromising its integrity.The base plate provides a sure footing for the can body during the seaming operation and the chuck fits snugly into the end (lid).[15] The heating process during canning appears to make dietary fiber more soluble, and therefore more readily fermented in the colon into gases and physiologically active byproducts.Since the refrigerator did not exist and industrial canning standards were not set in place it was very common for contaminated cans to slip onto the grocery store shelves.[17] According to The Fruits of Empire: Art, Food and the Politics of Race in the Age of American Expansion by Shana Klein, "Workers also suffered injuries, specifically bruised knuckles and open sores, from trimming and packaging pineapples.[21] Salt (sodium chloride), dissolved in water, is used in the canning process, which helps prevent spoilage and can improve sensory characteristics.[30] Botulism is a rare but serious paralytic illness, leading to paralysis that typically starts with the muscles of the face and then spreads towards the limbs.

Canning (disambiguation)Cannery Casino and HotelPyrolysisCaningcanned salmonfood preservationMason jarssteel and tin cansshelf lifelentilsBertrandNational Food Processors AssociationMason jarNicolas AppertNapoleonic Warsmilitary rationsGrande ArméeLouis PasteurpasteurizationFrench Empiretin canPhilippe de GirardPeter DurandBryan DonkinJohn HallBermondseyBritish ArmyRoyal NavyWilliam Edward ParryHMS FuryJames RossJohn FranklinLeopold McClintockBerthold-Weiss FactoryCsepelBudapeststatus symbolEuropenoveltysolderFranklin expeditionNorthwest PassageLong Beach, CaliforniaNew York CityoystersfruitsvegetablesCrimean WarAmerican Civil WarFranco-Prussian WarVictorianBritainUnderwoodNestléworking classWorld War Icalorietrenchbully beefpork and beansMaconochie's stewFrench ArmyFrench cuisinecoq au vinbeef bourguignonfrench onion soupVichyssoiseItalian Armyraviolispaghetti bologneseminestronepasta e fagioliArmeniaCan openersbayonetsAseptically processedretort poucheshome canningsterilizationClostridium botulinumbotulismacidityseafoodpoultryacidicpickledDouble seamdouble seamstin platetop hatrubberCan seamerspringbackwrinklestatistical process controlGaliciadietary fibervitaminslycopenePackaging and labelingFood safetylead poisoningbisphenol Aendocrine disruptorhigh blood pressureC. botulinumparalyticrespiratory failuremedical emergenciespublic healthRecessionElantoHelsinkiFinlandcocooningpreppersdoomerAmanda JonesvacuumCan openerCanned fishSalmon canneryFood industryFood dryingList of dried foodsThermal death time