History of the railway track

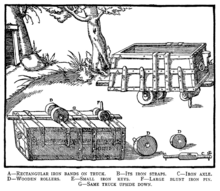

[3] Georg Agricola describes box-shaped carts, called "dogs", about half as large again as a wheelbarrow, fitted with a blunt vertical pin and wooden rollers running on iron axles.[6] Where space permitted round-section wooden tracks to take trucks with flanged wheels were installed: a painting from 1544 by the Flemish artist Lucas Gassel shows a coppermine with rails of this type emerging from an adit.[citation needed] Cast iron strips could be laid on top of timber rails, and the use of such materials probably occurred in 1738, but there are claims that this technology went back to 1716.[12] In 1767, Ketley ironworks began producing cast iron plates, which were fixed to the top of wooden rails with nails, to provide a more durable running surface.Railways of this kind were widely used in south Wales, particularly to transport limestone down to the ironworks, and then to take the iron to a canal, sometimes several miles away, which took the products to market.[16] The stone blocks had been assumed to be permanent, but experience quickly showed that they settled and gradually moved under traffic, creating chaotic track geometry and causing derailments.[citation needed] Cast iron edge rails were used by Thomas Dadford Jr. when building the Beaufort and Blaenavon lines to the Monmouthshire canal in 1793.[17] A short-lived alternative was the fish-bellied profile, first used by Thomas Barnes (1765–1801) at Walker Colliery, near Newcastle in 1798, which enabled rails to have a longer span between blocks.[19][page needed] The breakthrough came when John Birkinshaw of Bedlington Ironworks in Northumberland developed rolled wrought iron rails in 1820 in 15 feet (4.6 m) lengths, as used for the Stockton and Darlington Railway.Indenting of the sleeper was the problem; where the traffic was heavy, it became necessary to provide a sole plate under the rails to spread the load on the tie, partly vitiating the cost saving.[20][21] Henry Bessemer supplied 500 tons of steel blooms to the London and North Western Railway's rail mill at Crewe in 1860.[citation needed] Timber sleepers, that is transverse beams supporting the two rails that form the track, replaced the individual stone blocks formerly used.They have a significant advantage on weak formations and poor ballast conditions, as the bearing area is at a high level, immediately under the rail seat.Strap rails introduced in the late 18th century, of cast and later rolled iron were nailed to wooden supports via countersunk holes in the metal.Outside North America a wide variety of spring based fastening systems were later introduced in combination with baseplates and flat bottomed rail, these are now ubiquitous on main line high speed railways.It is more or less an accident of history that this gauge—which suited the wagons already in use at the colliery where George Stephenson had been an engine man—became the British standard gauge: it was exported to most of Europe and North America.The design varies considerably, but in many cases longitudinal timbers are supported directly on the cross-girders, with transoms and tiebars to retain the gauge, but of course with modern rails and base-plates or chairs.Under heavy usage, they indent the sleepers severely and the incremental cost of a base-plate appeared at this early date, to rule the flat bottom section out.The railway companies became persuaded that the traditional bullhead forms of track needed revision, and after some experimentation a new flat bottom rail format was adopted.[25] In this pioneering stage, some catastrophic mistakes in detailed design were made, but from about 1968 continuous welded rail became a reliable standard for universal installation on main and secondary routes.In the later 1950s, general track maintenance standards deteriorated rapidly due to labour shortages and, on some routes, faster freight train speeds.The gauge is set by the positioning of the cast-in fixings, so it is not a simple task to re-gauge existing track; it also creates problems with spot replacement of sleepers.At faster speeds on the turnout road, the divergence from the main route is much more gradual, and therefore a very considerable length of planning of the switch rail is required.Continuous Welded Rail (CWR) was developed in response to the observation that the bulk of track maintenance work takes place at the joints.As steel production and manufacturing processes improved, the rail lengths installed were progressively increased, and the logical extension of this would be to eliminate the joints altogether.If the long thin piece of metal could be constrained to prevent it from buckling (e.g. by being contained inside a tube) then it can resist a much higher compressive force.Originally the rails were physically heated to the stress-free temperature with propane gas heaters; they were then rattled with hand bars to eliminate any binding, preventing even expansion, and then clipped down.This was an alumino-thermic process in which a powder 'portion' was ignited; the aluminium was the fuel and a metallurgically appropriate composition of molten steel descended into the gap between the rail ends, contained in refractory moulds.The fish-plates at joints need to be removed and greased annually (the requirement was relaxed to bi-annually in 1993) and where this was omitted or where ballast conditions were especially weak, buckling took place in hot weather.In addition, if rails were allowed to creep, it was always possible that several successive joints might close up, so that the expansion gap was lost, with inevitable results at the onset of hot weather.

Railway trackPermanent way (disambiguation)Transylvania480 mmrailwaysleeperscast ironwrought ironangle ironIsambard Kingdom Brunelbroad gaugepile bridgeladder trackCreosotehardwoodsLucas GasselGeorg AgricolaElizabethan eraCumbriaMines RoyalwagonwayBroseleydrift minesSevern GorgeRiver SevernWollaton WagonwayNewcastle upon TynestaitheKetley ironworksstrap-iron railJohn CurrDuke of NorfolkBenjamin OutramButterley IronworksWilliam JessopSheffieldtrack geometryPenydarren or MerthyrtramwayRichard Trevithicklocomotivesteam enginesThomas Dadford Jr.BeaufortBlaenavonMonmouthshire canalinchesCromford CanalLoughboroughNanpantanGranthamBelvoir CastleScience Museum, LondonNewcastleGeorge StephensonJohn BirkinshawBedlington IronworksNorthumberlandStockton and Darlington RailwayRobert Forester MushetBessemerEbbw ValeDerby railway stationMidland RailwayEnglandHenry BessemerLondon and North Western Railwayopen hearth steelmakingWilliam SiemensGreat Western RailwayRailway sleeperRail fastening systemsRobert L. StevensTrack ballastGreat North of Scotland RailwaygravelRail gaugePompeiiBaulk roadWest Midlandsmixed gaugetimberBritish StandardsoftwoodhardwoodEastern RegionEast Coast Main LineCarlton-on-TrentPandrolbearing capacityTrack renewal trainsFighting Cocks branchRailroad switchthermal expansionflash-butt processThermitaluminiumClearance carList of track gaugesLoading gaugeOverhead linesRail lengthsRail profileRail sabotageRail tracksRail terminologyRailway platformStrap iron railStructure gaugeThird railTramway trackAgricola, GeorgiusHerbert Clark HooverThe Folio SocietyTracks(history)Axe tiesBallastBreather switchClip and scotchDate nailFastening systemFishplateMinimum radiusProfileTie/Sleeper