Evaporative cooler

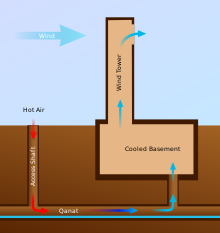

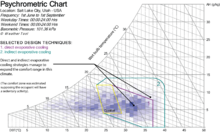

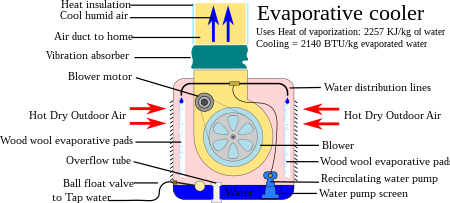

Passive evaporative cooling techniques in buildings have been a feature of desert architecture for centuries, but Western acceptance, study, innovation, and commercial application are all relatively recent.In 1974, William H. Goettl noticed how evaporative cooling technology works in arid climates, speculated that a combination unit could be more effective, and invented the "High Efficiency Astro Air Piggyback System", a combination refrigeration and evaporative cooling air conditioner.Evaporative cooling can be visualized using a psychrometric chart by finding the initial air condition and moving along a line of constant enthalpy toward a state of higher humidity.The figure showing the Salt Lake City weather data represents the typical summer climate (June to September).The colored lines illustrate the potential of direct and indirect evaporative cooling strategies to expand the comfort range in summer time.Evaporative cooling raises the internal humidity level significantly, which desert inhabitants may appreciate as the moist air re-hydrates dry skin and sinuses.Therefore, assessing typical climate data is an essential procedure to determine the potential of evaporative cooling strategies for a building.A general recommendation for applying direct evaporative cooling is to implement it in places where the wet-bulb temperature of the outdoor air does not exceed 22 °C (72 °F).[7] However, in the example of Salt Lake City, the upper limit for the direct evaporative cooling on psychrometric chart is 20 °C (68 °F).In dry, arid climates, the installation and operating cost of an evaporative cooler can be much lower than that of refrigerative air conditioning, often by 80% or so.For example, industrial plants, commercial kitchens, laundries, dry cleaners, greenhouses, spot cooling (loading docks, warehouses, factories, construction sites, athletic events, workshops, garages, and kennels) and confinement farming (poultry ranches, hog, and dairy) often employ evaporative cooling.In highly humid climates, evaporative cooling may have little thermal comfort benefit beyond the increased ventilation and air movement it provides.Trees transpire large amounts of water through pores in their leaves called stomata, and through this process of evaporative cooling, forests interact with climate at local and global scales.Benefits of evaporative cooling chambers for many rural communities in these regions include reduced post-harvest loss, less time spent traveling to the market, monetary savings, and increased availability of vegetables for consumption.The Apollo spacecraft used sublimators, compact and largely passive devices that dump waste heat in water vapor (steam) that is vented to space.Except in very dry climates, the single-stage (direct) cooler can increase relative humidity (RH) to a level that makes occupants uncomfortable.Single-stage direct evaporative coolers are typically small in size as they only consist of the membrane, water pump, and centrifugal fan.Depending on this mineral content and the evaporation rate, regular cleaning and maintenance are required to ensure optimal performance.Indirect cooler manufacturer uses the Maisotsenko cycle (M-Cycle), named after inventor and Professor Dr. Valeriy Maisotsenko, employs an iterative (multi-step) heat exchanger made of a thin recyclable membrane that can reduce the temperature of product air to below the wet-bulb temperature, and can approach the dew point.It may be used as supplementary cooling during times of extreme heat without placing significant additional burden on electrical infrastructure.However, regardless of these losses, the effective COP is still significantly higher than a conventional cooling system, even if water must first be purified by desalination.[21][22] In the newer but yet-to-be-commercialized "cold-SNAP" design from Harvard's Wyss Institute, a 3D-printed ceramic conducts heat but is half-coated with a hydrophobic material that serves as a moisture barrier.In the first stage of a two-stage cooler, warm air is pre-cooled indirectly without adding humidity (by passing inside a heat exchanger that is cooled by evaporation on the outside).In another hybrid design, direct or indirect cooling has been combined with vapor-compression or absorption air conditioning to increase the overall efficiency and/or to reduce the temperature below the wet-bulb limit.[25] Traditionally, evaporative cooler pads consist of excelsior (aspen wood fiber) inside a containment net, but more modern materials, such as some plastics and melamine paper, are entering use as cooler-pad media.Therefore, shading is advisable in all circumstances, though the vertical aspect of the pads, and insulation between the exterior and interior horizontal (upwards facing) surfaces to minimise heat transfer will suffice.By optimizing the placement of the cooled-air inlet, along with the layout of the house passages, related doors, and room windows, the system can be used most effectively to direct the cooled air to the required areas.A well-designed layout can effectively scavenge and expel the hot air from desired areas without the need for an above-ceiling ducted venting system.Continuous airflow is essential, so the exhaust windows or vents must not restrict the volume and passage of air being introduced by the evaporative cooling machine.Because evaporative coolers perform best in dry conditions, they are widely used and most effective in arid, desert regions such as the southwestern USA, northern Mexico, and Rajasthan.

Evaporative cooling (atomic physics)Passive coolingevaporationair conditioningvapor-compressionabsorptionenthalpy of vaporizationphase transitiondry-bulb temperaturewet-bulbrelative humidityarid climateswindcatcherancient EgyptPersiaexcelsior (wood wool)float valvecentrifugal fanAmerican SouthwestsalasabilRed FortMirzapurUttar Pradeshvapor-compression refrigerationabsorption refrigerationsensible heatlatent heatenthalpyisenthalpic processpsychrometric chartperspirationphase transition from solid to vaporanti-greenhouse effectdesiccantlatent heat of fusionliquidlatent heat of vaporizationqanatswindcatchersmashrabiyasearthenwarefrescoesbotijoCoolgardie saferanch housethermal comfortwet-bulb temperaturewet-bulb depressionclimateshumidityAlbuquerqueDenverEl PasoFresnoSalt Lake CityTucsonAustraliahumidifiersmonsoon season in New Mexico and central and southern Arizonalaundriesdry cleanersgreenhousesventilationstomataevaporative cooling chamberspot-in-pot refrigeratorscryogenicvapor pressurehelium1-K pothelium-3cryocoolerscryostatsdilution refrigeratorsBose–Einstein condensationspacecraftthermal radiationSpace ShuttleApollo command and service modulelunar moduleportable life support systemammoniasublimatorsfuel cellsheat exchangerdew pointStirling enginesAtmospheric water generatorscoefficient of performancesolar thermal energypassive daytime radiative coolingthermal insulationzero energyclimatic zonerefrigerationexcelsiorwood fibermelaminechillerssaturationCooling towerhyperboloidRankine power cyclemicrometresFlash evaporationhumidifierpsychrometricsdewpointLas Vegasrule of thumbdesertsouthwestern USAMexicoRajasthancompressorozone depletionremote controlstatic electricitydehumidificationevaporative coolercorrosioncondensationmineralWood woolwinterizedsick building syndrome