Mercury-arc valve

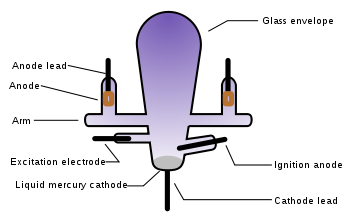

Mercury-arc rectifiers or "converters" were used for charging storage batteries, arc lighting systems,[6] the DC traction motors for trolleybuses, trams, and subways, and electroplating equipment.Operation of the rectifier relies on an electrical arc discharge between electrodes in a sealed envelope containing mercury vapor at very low pressure.The mercury ions are attracted towards the cathode, and the resulting ionic bombardment of the pool maintains the temperature of the emission spot, so long as a current of a few amperes continues.While the current is carried by electrons, the positive ions returning to the cathode allow the conduction path to be largely unaffected by the space charge effects which limit the performance of vacuum tubes.Hot-cathode, gas discharge tubes such as the thyratron may also achieve similar levels of efficiency but heated cathode filaments are delicate and have a short operating life when used at high current.The temperature of the envelope must be carefully controlled, since the behaviour of the arc is determined largely by the vapor pressure of the mercury, which in turn is set by the coolest spot on the enclosure wall.Development of high-current rectifiers required leadwire materials and glass with very similar coefficients of thermal expansion in order to prevent leakage of air into the envelope.One example of the problems caused by backfire occurred in 1960 subsequent to the electrification of the Glasgow North Suburban Railway where steam services had to be re-introduced after several mishaps.However, the tall porcelain column required to house the grading electrodes was more difficult to cool than the steel tank at cathode potential, so the usable current rating was limited to about 200–300 A per anode.The direct current produced by a single-phase rectifier thus contained a varying component (ripple) at twice the power supply frequency, which was undesirable in many applications for DC.The solution was to use two-, three-, or even six-phase AC power supplies so that the rectified current would maintain a more constant voltage level.In the 1960s, solid-state silicon devices, first diodes and then thyristors, replaced all lower-power and lower voltage rectifier applications of mercury arc tubes.Several electric locomotives, including the New Haven EP5 and the Virginian EL-C, carried ignitrons on board to rectify incoming AC to traction motor DC.The largest ever mercury-arc rectifiers, built by English Electric, were rated at 150 kV, 1800 A and were used until 2004 at the Nelson River DC Transmission System high-voltage DC-power-transmission project.Mercury arc valves were used extensively in DC power systems on London Underground,[14] and two were still observed to be in operation in 2000 at the disused deep-level air-raid shelter at Belsize Park.This led to the mercury-arc rectifier at the Goodge Street shelter featuring in an early episode of Doctor Who as an alien brain, cast for its "eerie glow".[16] Auckland's Museum Of Transport And Technology (MOTAT) still employs a Mercury arc valve to provide power to the tram which carries visitors between its two sites.

Beromünster AM transmitterSwitzerlandrectifiervoltagecurrentalternating currentdirect currentcold cathodegas-filled tubemercuryamperePeter Cooper Hewittelectric railwaysstreetcarselectric locomotivestransmittershigh-voltage direct currentsemiconductordiodesthyristorsgate turn-off thyristorsJules Jaminrotary convertersarc lightingtrolleybusessemiconductor rectifierselectrodescathodeelectronsanodesionizationspace chargevacuum tubesthyratronvapor pressuremillipascalsultravioletgraphiteelectromagnetmagnetostrictionbimetallic stripradiotelegraphyMorse keyinvertertriodeHVDC Inter-IslandNew ZealandresistorcapacitorUno LammSwedenGotlandfrequencytwo-, three-, or even six-phasecenter taptransformermetal rectifiersEdisonDC power gridssolid-stateNew Haven EP5Virginian EL-CignitronskilovoltManitoba HydroHVDC KingsnorthKingsnorth power stationLondonEnglish ElectricNelson River DC Transmission SystemHVDC Vancouver IslandSouth AfricanMombasa PolytechnicLondon Undergrounddeep-level air-raid shelterBelsize ParkGoodge StreetDoctor WhoIgnitronamplifiertelephonemodulateaudionComptes rendus de l'Académie des SciencesThe London, Edinburgh, and Dublin Philosophical Magazine and Journal of ScienceInternational Textbook CompanyPergamon PressAmerican Radio Relay LeagueProject GutenbergElectronic componentsSemiconductordevicesMOS transistorsTransistorBiCMOSBioFETChemical field-effect transistorComplementary MOSDepletion-load NMOSFin field-effect transistorFloating-gate MOSFETInsulated-gate bipolar transistorMOS field-effect transistorMulti-gate field-effect transistorPower MOSFETThin-film transistorOther transistorsBipolar junction transistorDarlington transistorDiffused junction transistorField-effect transistorJunction Gate FET (JFET)Organic FET (OFET)Light-emitting transistorOrganic LET (OLET)Pentode transistorPoint-contact transistorProgrammable unijunction transistorStatic induction transistorTetrode transistorUnijunction transistorAvalanche diodeConstant-current diodeGunn diodeLaser diodeLight-emitting diodeOrganic light-emitting diode