Screen printing

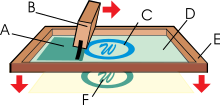

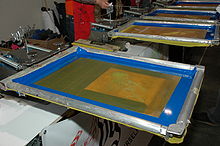

This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed.Roy Beck, Charles Peter and Edward Owens studied and experimented with chromic acid salt sensitized emulsions for photo-reactive stencils.[3] "Serigraphy" is a compound word formed from Latin "sēricum" (silk) and Greek "graphein" (to write or draw).Since rudimentary screenprinting materials are so affordable and readily available, it has been used frequently in underground settings and subcultures, and the non-professional look of such DIY culture screenprints have become a significant cultural aesthetic seen on movie posters, record album covers, flyers, shirts, commercial fonts in advertising, in artwork and elsewhere.Warhol was supported in his production by master screen printer Michel Caza, a founding member of Fespa.American entrepreneur, artist and inventor Michael Vasilantone started to use, develop, and sell a rotatable multicolour garment screen printing machine in 1960.The frame which holds the mesh could be made of diverse materials, such as wood, metal, or aluminum, depending on the sophistication of the machine or the artisan procedure.A stencil is formed by blocking off parts of the screen in the negative image of the design to be printed; that is, the open spaces are where the ink will appear on the substrate.They are then washed away using a water spray, leaving behind a clean area in the mesh with the identical shape as the desired image, which will allow passage of ink.Different inks can be used to work with a variety of materials, such as textiles, ceramics,[13] wood, paper, glass, metal, and plastic.[18] These machines are much faster and use either pneumatic pressure generated by air compressors or use electric motors to draw the squeegees, rotate and raise or lower pallets removing much of the manual labour from the task and use UV for instant image curing - resulting in significant reductions in operator fatigue as well as more consistent results.[20] Typical names for these service print overlays include tSilk/bSilk aka PLC/PLS[21][nb 1] or TSK/BSK (EAGLE), F.SilkS/B.SilkS (KiCad), PosiTop/PosiBot (TARGET), silkTop/silkBottom (Fritzing), SST/SSB (OrCAD), ST.PHO/SB.PHO (PADS), SEVS/SERS (WEdirekt)[22] or GTO/GBO (Gerber and many others[23]).Its versatility and ability to deposit thick layers of inks make it ideal for creating conductive tracks, sensors, and other electronic components.Furthermore, screen printing offers advantages such as high throughput, low production costs, and compatibility with a wide range of substrates, including flexible materials.Fine-line resolution, compatibility with advanced materials, and the need for precise registration pose ongoing research and development opportunities.However, continuous advancements in ink formulations, equipment, and process optimization are paving the way for exciting future possibilities, including the integration of printed electronics into Internet of Things (IoT) devices, energy harvesting systems, and more.

Print Screenscreen paintingHistory of printingWoodblock printingMovable typeIntaglio (printmaking)Printing pressEtchingMezzotintRelief printingAquatintLithographyChromolithographyRotary pressHectographOffset printingHot metal typesettingMimeographDaisy wheel printingPhotostat and rectigraphSpirit duplicatorDot matrix printingXerographySpark printingPhototypesettingInkjet printingDye-sublimationLaser printingThermal printingSolid ink printingThermal-transfer printing3D printingDigital printingsubstratestencilsqueegeeaperturesHeart Mountain War Relocation CenterSong dynastyactinic lightchromate and dichromategelatinNational Serigraph SocietyMax Arthur CohnAnthony VelonisHyman WarsagerHarold AmbellanDesigned TilesundergroundsubculturesDIY cultureAndy WarholMarilyn DiptychMarilyn MonroeSister Mary Corita KentbowlingArthur OkamuraRobert RauschenbergRoy LichtensteinHarry Gottliebsynthetic polymerNewtoncentimetermacro photophoto emulsionphotocopiedphotosensitive emulsionultravioletformaldehydeRongaliteCMYK colour modelhalftonesPlastisolphthalatetextile printingprinted electronicsroll-to-rollBalloonsClothingDecalsMedical devicescircuit board printingSnowboardfabricThick film technologyPinballDrinkwarepassivationSolar wafersprinting presseselectronic design automationlayer stackprinted circuit boardGerber filessolder-stop layersTARGETFritzingWEdirektInk jetGerberfilename extensionsthrough-holeCadSoft Computer, Inc.Würth Elektronik GmbH & Co. KGAltium LimitedSaff, Donald