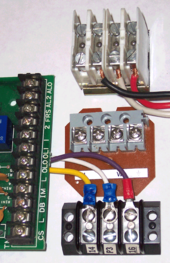

Screw terminal

Grounding screws are often color-coded green and, when used on consumer electronics, often have a washer with gripping "teeth", to ensure better connections.Some designs provide features that allow the flow of molten solder to ensure a better connection between the circuit traces of the board and the electrical equipment which is meant to be controlled or fed appropriate power.While wires may be crimped, they should not be heavily tinned with solder prior to installation in a screw terminal, since the soft metal will cold flow, resulting in a loose connection and possible fire hazard.The terminals easily can be re-used in the field, allowing for the replacement of wires or equipment, generally with standard hand tools.When properly tightened, the connections are physically and electrically secure because they firmly contact a large section of wire.The use of screw terminal "chocolate blocks" in building wiring installations has sharply declined in favour of crimp, push, and twist type connectors which are and easier to fit, and less vulnerable to working loose.

electrical connectionset screwferrulescrewdriverhex keylight fixturesbuilding wiringelectricityelectrical outletsluminairesswitchesmajor appliancesclothes dryerschassis groundrecord playersurge protectorpublic addressspeakersAlarm systemscolor-codedconsumer electronicswasherbus barpower distributionbinding postsbanana connectorssoldercold flowVibrationcorrosionChocboxWire nutEuroblock