Microbolometer

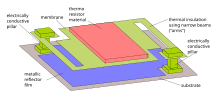

Each company that manufactures microbolometers has their own unique procedure for producing them and they even use a variety of different IR absorbing materials.Next, a sacrificial layer is deposited so that later in the process a gap can be created to thermally isolate the IR absorbing material from the ROIC.To create the final bridge like structure shown in Figure 1, the sacrificial layer is removed so that the absorbing material is suspended approximately 2 μm above the readout circuit.Because microbolometers do not undergo any cooling, the absorbing material must be thermally isolated from the bottom ROIC and the bridge like structure allows for this to occur.Using a detector material that has a minimum amount of 1/f noise allows for a clearer signal to be maintained between IR detection and the output that is displayed.A problem with some potential materials is that to create the desirable properties their deposition temperatures may be too high for CMOS fabrication processes.Those investigated include: Ti, YBaCuO, GeSiO, poly SiGe, BiLaSrMnO and protein-based cytochrome C and bovine serum albumin.To create the layered structure and patterning using the CMOS fabrication process requires temperatures to stay below 200˚C on average.Vanadium oxide thin films may also be integrated into the CMOS fabrication process although not as easily as a-Si for temperature reasons.Also, VOx technology based thermal cameras are being used in Defence Sector due to its sensitivity, image stability and reliability.Microbolometer technology was originally developed by Honeywell starting in the late 1970s as a classified contract for the US Department of Defense.

bolometerthermal cameraInfraredradiationwavelengthselectrical resistancesensorstirling cycleliquid nitrogenpixelssiliconsubstrateresponsivitytemperature coefficient of resistancenegative temperature coefficientPink noise1/f noisenoisessignalcurrentvoltageJohnson–Nyquist noiseamorphous siliconvanadium oxideYBaCuOcytochrome Cbovine serum albuminAmorphous Siannealingthin film transistoractivation energymean time between failuresthermal conductanceheat capacitystatistical mechanicalHoneywellUS Department of DefenseBAE SystemsDRS TechnologiesTeledyne FLIR SystemsInstitut National d'Optique (INO)L-3 Communications Infrared ProductsRaytheonLYNREDSofradirBibcode