Utility frequency

In the late 19th century, designers would pick a relatively high frequency for systems featuring transformers and arc lights, so as to economize on transformer materials and to reduce visible flickering of the lamps, but would pick a lower frequency for systems with long transmission lines or feeding primarily motor loads or rotary converters for producing direct current.When large central generating stations became practical, the choice of frequency was made based on the nature of the intended load.For very slow prime mover speeds, it would be costly to build a generator with enough poles to provide a high AC frequency.While belt drives were common as a way to increase speed of slow engines, in very large ratings (thousands of kilowatts) these were expensive, inefficient, and unreliable.Prior to the development of mercury arc valve rectifiers, rotary converters were used to produce DC power from AC.The use of AC eliminated the need for spinning DC voltage conversion motor-generators that require regular maintenance and monitoring.In the early incandescent lighting period, single-phase AC was common and typical generators were 8-pole machines operated at 2,000 RPM, giving a frequency of 133 hertz.[6] The operation of Tesla's induction motor, licensed by Westinghouse in 1888, required a lower frequency than the 133 Hz common for lighting systems at that time.The first generators at the Niagara Falls project, built by Westinghouse in 1895, were 25 Hz, because the turbine speed had already been set before alternating current power transmission had been definitively selected.[3] Because the Niagara project was so influential on electric power systems design, 25 Hz prevailed as the North American standard for low-frequency AC.A General Electric study concluded that 40 Hz would have been a good compromise between lighting, motor, and transmission needs, given the materials and equipment available in the first quarter of the 20th century.Industrial plants and mines in North America and Australia sometimes were built with 40 Hz electrical systems which were maintained until too uneconomic to continue.[18] A frequency of 25 Hz is used for the Austrian Mariazell Railway, as well as Amtrak and SEPTA's traction power systems in the United States.Nikola Tesla demonstrated the concept of clocks synchronized by line frequency at the 1893 Chicago Worlds fair.The Hammond Organ also depends on a synchronous AC clock motor to maintain the correct speed of its internal "tone wheel" generator, thus keeping all notes pitch-perfect.Today, AC power network operators regulate the daily average frequency so that clocks stay within a few seconds of the correct time.[22][23] Real-time frequency meters for power generation in the United Kingdom are available online – an official one for the National Grid, and an unofficial one maintained by Dynamic Demand.[29] Modern alternating-current grids use precise frequency control as an out-of-band signal to coordinate generators connected the network.[31] Indeed, a 2017 trial for CAISO discovered that solar plants could respond to the signal faster than traditional generators, because they did not need to accelerate a rotating mass.During a severe failure of generators or transmission lines, the ensuing load-generation imbalance will induce variation in local power system frequencies.[37][38] The coefficient B traditionally has a negative value, so that when the frequency is lower than the target, area power production should increase; its magnitude is usually on the order of MW/dHz.In the 1950s, Nathan Cohn popularized the practice in a series of articles, arguing that load-frequency control minimized the adjustment necessary for changes in load.[40] In particular, Cohn supposed that all regions of the grid shared a common linear regime, with location-invariant[41] frequency change per additional loading (df/dL).and one region experienced a temporary fault or other generation-load mismatch, then adjacent generators would observe a decrease in frequency but a counterbalancing increase in outward tieline power flow, giving no ACE.The importance of this parameter increases when the traditional synchronous generators are replaced by the variable renewable energy (VRE) inverter-based resources (IBR).Since the IBRs are not electromechanically coupled into the power grid, a system with high VRE penetration might exhibit large RoCoF values that can cause problems with the operation of the system due to stress placed onto the remaining synchronous generators, triggering of the protection devices and load shedding.[43] As of 2017, regulations for some grids required the power plants to tolerate RoCoF of 1–4 Hz/s, the upper limit being a very high value, an order of magnitude higher than the design target of a typical older gas turbine generator.In the US, the controllable grid interface at the National Renewable Energy Laboratory is the only facility that allows testing of multi-MW units[45] (up to 7 MVA).This helped to prevent power line hum and magnetic interference from causing visible beat frequencies in the displayed picture of early analogue TV receivers particularly from the mains transformer.The elimination of transformers by the use of AC/DC receivers, and other changes to set design helped minimise the effect and some countries now use a vertical rate that is an approximation to the supply frequency (most notably 60 Hz areas).

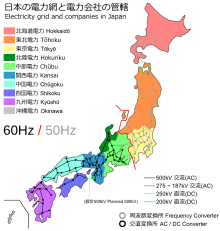

60 CyclesFailure rateAmerican EnglishBritish Englishfrequencyalternating currentwide area synchronous gridpower stationend-userAmericasmains electricity by countryTime error correction (TEC)transformersarc lightsrotary convertersdirect currentincandescent lightingcommutatorelectric motorsarc lampsmercury-vapor lampsfluorescent lampsinductanceinduction motorturbinesteam turbinescommutatorsmercury arc valverectifiersElectric power transmissionSynchronization (alternating current)War of the currentssteam enginewater turbineelectrical generatorurban legendsmonopolyLauffen-Frankfurt linkWestinghouse ElectricMill CreekRedlands, CaliforniaNiagara Falls projectGeneral ElectricLauffen-Frankfurt demonstrationNewcastle-upon-Tyne Electric Supply CompanyNational Grid (UK)hydroelectricMechanicville Hydroelectric Plantfrequency changersGanz CompanyStandardizationNational GridWorld War IIVerband der ElektrotechnikOntarioQuebecrailway electrificationSir Adam Beck 1Rankine generating stationsNiagara Falls15 kV ACGermanyAustriaSwitzerlandSwedenNorwaystatic inverterSouthern California EdisonShin ShinanoMinami-FukumitsuHigashi-Shimizu Frequency Convertercalcium carbideDeptford Power StationBritish East AfricaList of railway electrification systemstraction power networksMariazell RailwayAmtraktraction powerstationscomputer powerMIL-STD-704Henry WarrenNikola Tesla1893 Chicago Worlds fairHammond Organsynchronous grid of Continental EuropeInternational Atomic TimeNorth AmericaEastern InterconnectionTexas InterconnectionWestern InterconnectionFrequency Monitoring Network (FNET)University of TennesseeFederal Energy Regulatory CommissionNorth American Electric Reliability CorporationModern alternating-current gridsout-of-band signalgeneratorrotational energyAutomatic generation controlgovernordecasecondsFlywheelinvertersolar farmspower plantsprogrammedaccelerate a rotatingoutagesinterconnectionvoltageprotective relaysload sheddingpreserve the operation of at least part of the networkcontractsdampingoverlinestie-linenumerically integratedaverageon the order ofpost-war periodNathan Cohnlinear regimederivativesynchronous generators